Why Consider Gravel and Crushed Stone for Your Industrial Facility?

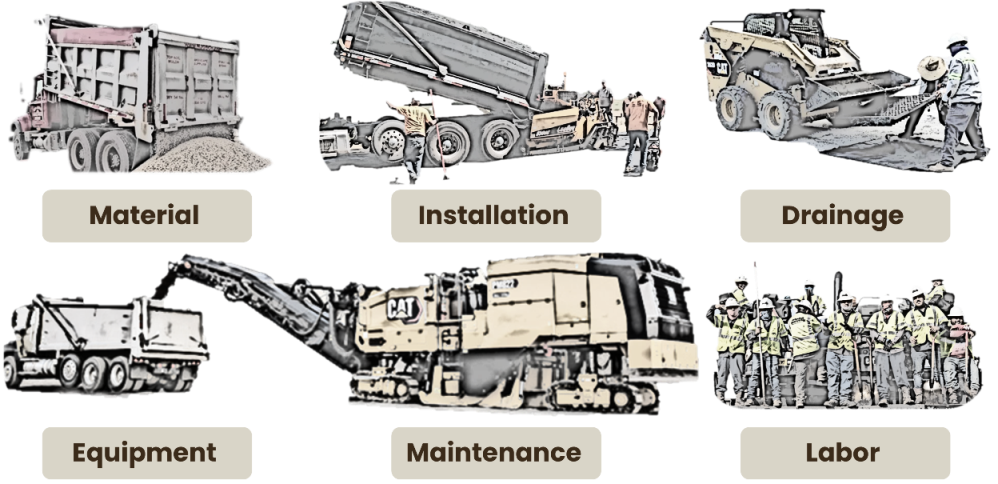

For industrial and commercial property managers seeking a cost-effective, durable, and low-maintenance alternative to traditional paved surfaces, gravel and crushed stone offer clear advantages. Their permeability can eliminate expensive drainage systems, their installation requires less labor and equipment, and their long-term durability reduces maintenance costs.

For businesses requiring enhanced load-bearing capacity or erosion control, the addition of permeable paver grids can further reinforce the surface while maintaining the benefits of aggregate materials. Additionally, these solutions are environmentally friendly, reducing runoff and helping to replenish groundwater supplies naturally.

By choosing gravel and crushed stone, industrial facilities and property managers can achieve a resilient and cost-efficient parking or storage surface that meets operational needs without the high costs associated with traditional paving materials. In addition, Federal Government guidelines highlight the value of aggregate road construction for low to mid range load bearing requirements.